- Home

- Packaging Products

- Film Slitting Machine Market Size, Future Growth and Forecast 2033

Film Slitting Machine Market Size, Future Growth and Forecast 2033

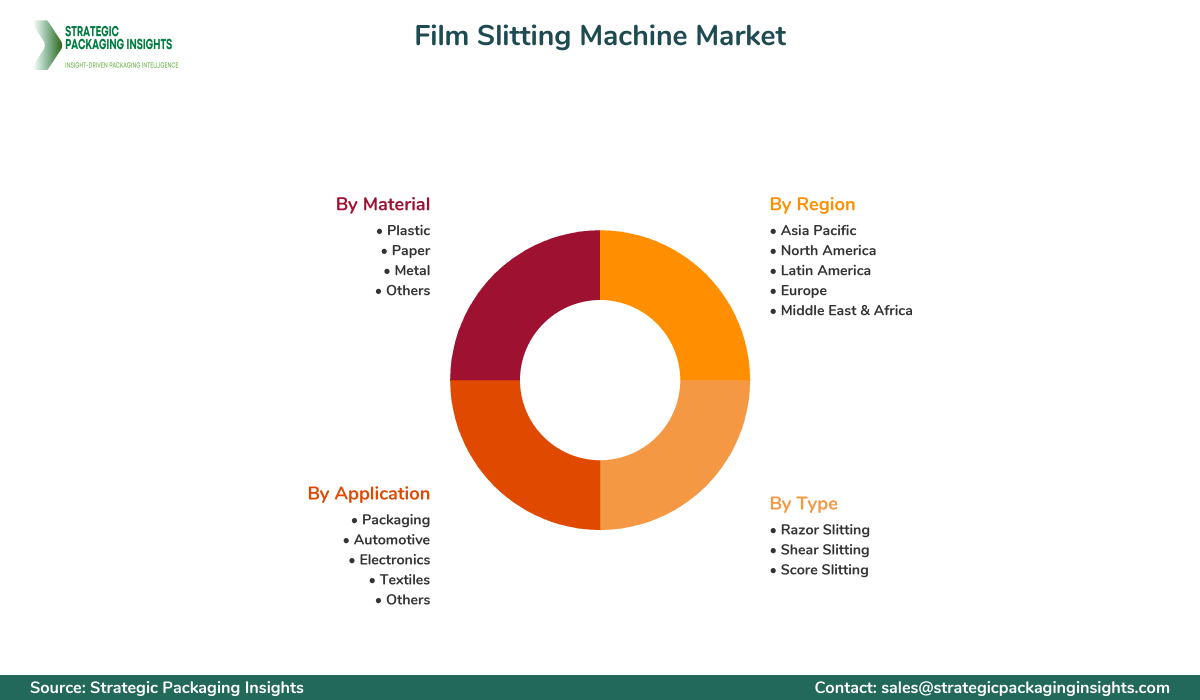

Film Slitting Machine Market Segments - by Type (Razor Slitting, Shear Slitting, Score Slitting), Application (Packaging, Automotive, Electronics, Textiles, Others), Material (Plastic, Paper, Metal, Others), and Region (Asia Pacific, North America, Latin America, Europe, and Middle East & Africa) - Market Dynamics, Growth Opportunities, Strategic Drivers, and PESTLE Outlook (2025–2033)

Film Slitting Machine Market Outlook

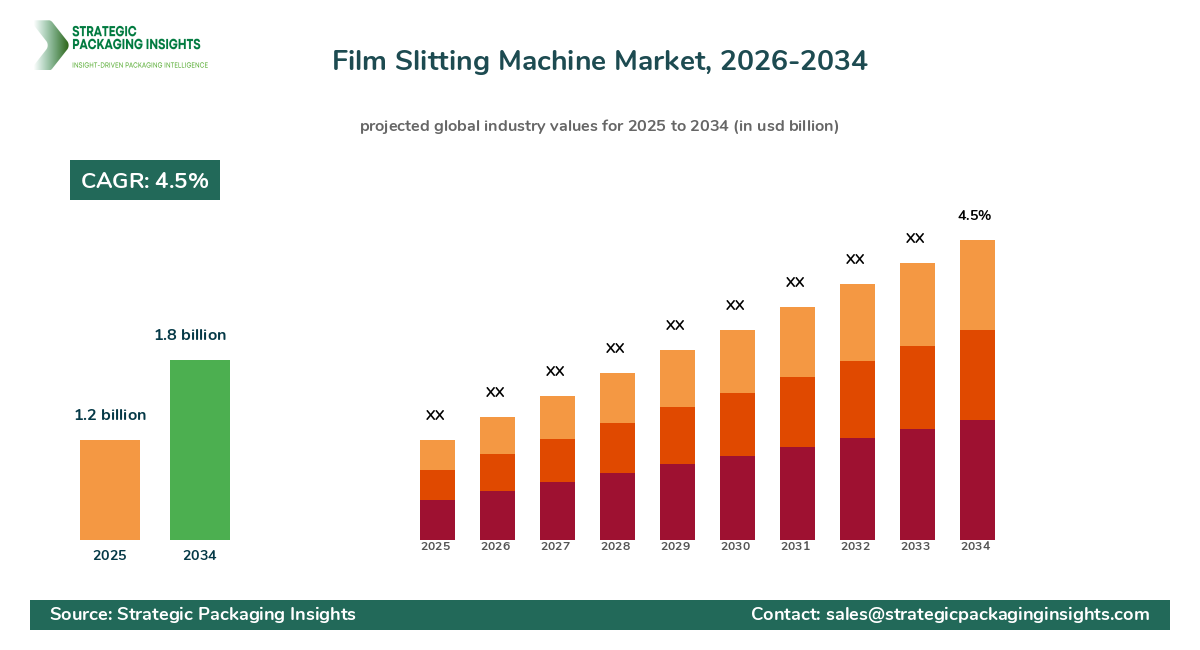

The film slitting machine market was valued at $1.2 billion in 2024 and is projected to reach $1.8 billion by 2033, growing at a CAGR of 4.5% during the forecast period 2025–2033. This market is driven by the increasing demand for flexible packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods. The rise in e-commerce and the need for efficient packaging solutions have further propelled the demand for film slitting machines. Additionally, technological advancements in slitting machines, such as automation and precision cutting, are enhancing operational efficiency and reducing waste, thereby driving market growth.

However, the market faces certain restraints, including high initial investment costs and the need for skilled operators to manage advanced machinery. Regulatory challenges related to environmental concerns and waste management also pose significant hurdles. Despite these challenges, the market holds substantial growth potential due to the increasing adoption of sustainable and eco-friendly packaging materials, which require precise slitting processes. The ongoing trend towards miniaturization and customization in packaging is expected to create new opportunities for market players.

Report Scope

| Attributes | Details |

| Report Title | Film Slitting Machine Market Size, Future Growth and Forecast 2033 |

| Base Year | 2025 |

| Historic Data | 2018-2024 |

| Forecast Period | 2026-2034 |

| Number of Pages | 219 |

| Type | Razor Slitting, Shear Slitting, Score Slitting |

| Application | Packaging, Automotive, Electronics, Textiles, Others |

| Material | Plastic, Paper, Metal, Others |

| Region | Asia Pacific, North America, Latin America, Europe, Middle East & Africa |

| Customization Available | Yes* |

Opportunities & Threats

The film slitting machine market presents numerous opportunities, particularly with the growing emphasis on sustainable packaging solutions. As consumers and regulatory bodies push for environmentally friendly packaging, manufacturers are increasingly adopting biodegradable and recyclable materials. This shift necessitates advanced slitting technologies capable of handling diverse material properties, thus driving demand for innovative slitting machines. Additionally, the rise of smart packaging, which integrates digital technologies for enhanced functionality, offers new avenues for growth. Film slitting machines that can accommodate these advanced materials and designs are likely to see increased adoption.

Another significant opportunity lies in the expansion of the e-commerce sector. With the surge in online shopping, there is a heightened demand for efficient and protective packaging solutions. Film slitting machines play a crucial role in producing packaging materials that meet these requirements. Furthermore, the increasing globalization of supply chains necessitates standardized packaging solutions, which can be efficiently produced using advanced slitting technologies. Companies that invest in R&D to develop machines that cater to these evolving needs are poised to gain a competitive edge.

Despite these opportunities, the market faces threats from fluctuating raw material prices and stringent environmental regulations. The cost of materials such as plastics and metals can significantly impact the profitability of film slitting machine manufacturers. Additionally, regulatory pressures to reduce plastic waste and carbon emissions may require companies to invest in costly upgrades or alternative technologies. These factors could potentially hinder market growth if not addressed proactively.

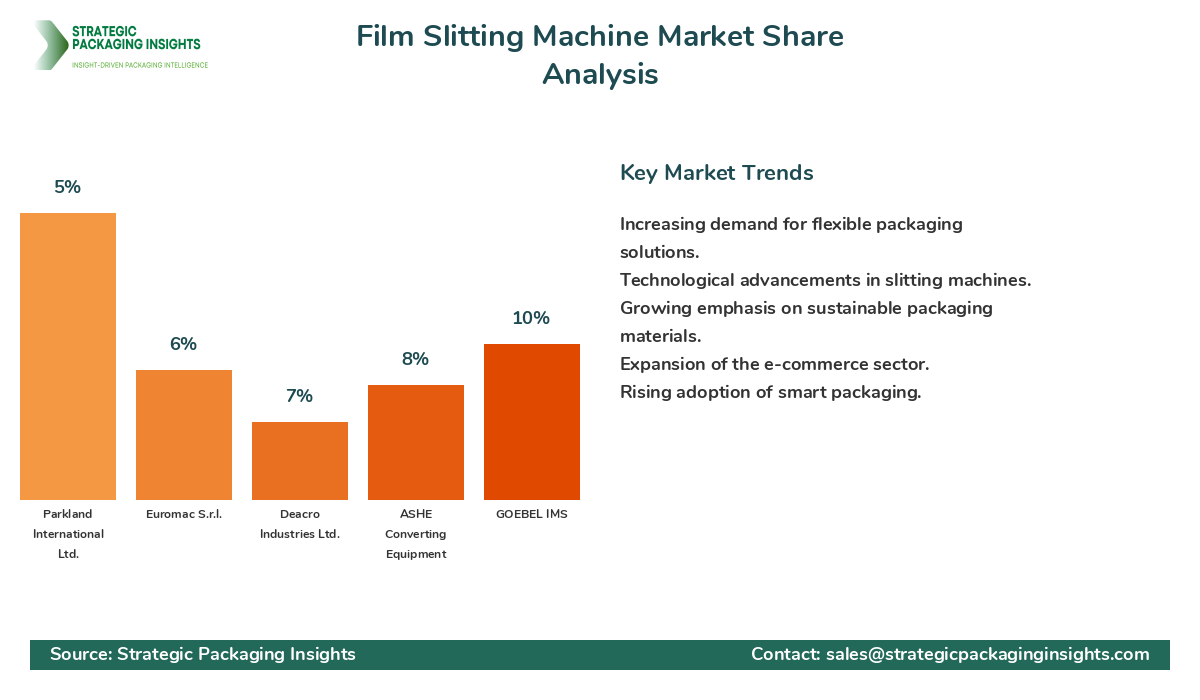

The film slitting machine market is characterized by a competitive landscape with several key players vying for market share. Companies such as Atlas Converting Equipment Ltd., Kampf Schneid- und Wickeltechnik GmbH & Co. KG, and GOEBEL IMS are prominent players in this space, each holding a significant share of the market. Atlas Converting Equipment Ltd. is known for its innovative solutions and has a strong presence in the European market. Kampf Schneid- und Wickeltechnik GmbH & Co. KG, on the other hand, has a robust portfolio of slitting machines catering to various industries, including packaging and textiles.

GOEBEL IMS, a leading manufacturer of slitting and winding machines, has a strong foothold in the global market, particularly in the Asia Pacific region. The company is renowned for its high-quality machines that offer precision and efficiency. Other notable players include ASHE Converting Equipment, which specializes in custom-built slitting machines, and Deacro Industries Ltd., known for its advanced technology and customer-centric approach. These companies are continuously investing in R&D to enhance their product offerings and maintain their competitive edge.

In addition to these major players, several regional and local manufacturers contribute to the market dynamics. Companies like Euromac S.r.l. and Parkland International Ltd. have carved out niches in specific regions, offering tailored solutions to meet local demands. The competitive landscape is further intensified by the presence of emerging players who are leveraging technological advancements to introduce innovative products. This dynamic environment fosters continuous innovation and drives the overall growth of the film slitting machine market.

Key Highlights Film Slitting Machine Market

- Increasing demand for flexible packaging solutions across various industries.

- Technological advancements in slitting machines enhancing operational efficiency.

- Growing emphasis on sustainable and eco-friendly packaging materials.

- Expansion of the e-commerce sector driving demand for efficient packaging solutions.

- Regulatory challenges related to environmental concerns and waste management.

- Rising adoption of smart packaging integrating digital technologies.

- Fluctuating raw material prices impacting profitability.

- Significant growth potential in the Asia Pacific region.

- Continuous innovation by key market players to maintain competitive edge.

- Increasing globalization of supply chains necessitating standardized packaging solutions.

Top Countries Insights in Film Slitting Machine

The United States is a leading market for film slitting machines, with a market size of $300 million and a CAGR of 5%. The country's robust packaging industry, coupled with technological advancements, drives demand. The focus on sustainable packaging solutions further fuels growth, although regulatory challenges related to environmental concerns pose hurdles.

China, with a market size of $250 million and a CAGR of 7%, is another significant player. The country's booming e-commerce sector and increasing industrialization drive demand for efficient packaging solutions. However, the market faces challenges from fluctuating raw material prices and stringent environmental regulations.

Germany, with a market size of $200 million and a CAGR of 4%, is a key market in Europe. The country's strong manufacturing base and emphasis on precision engineering drive demand for advanced slitting machines. The focus on sustainability and innovation further supports market growth.

India, with a market size of $150 million and a CAGR of 8%, is an emerging market with significant growth potential. The country's expanding middle class and increasing consumer spending drive demand for packaging solutions. However, the market faces challenges from infrastructure constraints and regulatory hurdles.

Japan, with a market size of $100 million and a CAGR of 3%, is a mature market with a focus on technological innovation. The country's emphasis on quality and precision drives demand for advanced slitting machines. However, the market faces challenges from an aging population and declining domestic demand.

Value Chain Profitability Analysis

The film slitting machine market's value chain involves several key stakeholders, including raw material suppliers, manufacturers, distributors, and end-users. Raw material suppliers provide essential inputs such as metals and plastics, which are crucial for manufacturing slitting machines. Manufacturers, who are at the core of the value chain, design and produce machines that meet specific industry requirements. Distributors play a vital role in ensuring the availability of these machines across various regions, while end-users, including packaging companies and converters, utilize these machines to Produce Packaging materials.

Profit margins vary across the value chain, with manufacturers typically capturing the largest share due to the high value-added nature of their products. Distributors also enjoy healthy margins, particularly those with strong regional networks and customer relationships. End-users, while benefiting from the efficiency and precision of advanced slitting machines, face pressure to optimize costs and improve operational efficiency. The ongoing digital transformation in the industry is reshaping the value chain, with technology platforms and service providers capturing increasing shares of market value. These stakeholders offer solutions that enhance machine performance, reduce downtime, and improve overall productivity.

Evolving Market Dynamics (2018–2024) and Strategic Foresight (2025–2033)

The film slitting machine market has undergone significant changes between 2018 and 2024, driven by technological advancements and shifting consumer preferences. During this period, the market experienced steady growth, with a CAGR of 3.5%, as manufacturers focused on enhancing machine efficiency and precision. The rise of e-commerce and the demand for flexible packaging solutions were key drivers, while regulatory challenges related to environmental concerns posed constraints.

Looking ahead to 2025–2033, the market is expected to grow at a CAGR of 4.5%, driven by the increasing adoption of sustainable packaging materials and the expansion of the e-commerce sector. Technological innovations, such as automation and digital integration, will play a crucial role in shaping market dynamics. Companies that invest in R&D to develop advanced slitting machines capable of handling diverse materials and designs are likely to gain a competitive edge. The focus on sustainability and efficiency will continue to drive demand, while regulatory pressures and fluctuating raw material prices remain key challenges.

Film Slitting Machine Market Segments Insights

Type Analysis

The film slitting machine market is segmented by type into razor slitting, shear slitting, and score slitting. Razor slitting is widely used for its simplicity and cost-effectiveness, particularly in applications involving thin films. Shear slitting, known for its precision and clean cuts, is preferred in industries requiring high-quality finishes, such as packaging and textiles. Score slitting, while less common, is utilized for specific applications where controlled tearing is required. The choice of slitting type depends on the material properties and desired end-product quality, with manufacturers continuously innovating to enhance performance and efficiency.

Razor slitting machines are popular due to their low maintenance requirements and ease of operation. They are particularly suited for high-speed operations and are commonly used in the production of plastic films. Shear slitting machines, on the other hand, are favored for their ability to handle thicker materials and produce precise cuts. These machines are often used in the production of paper and metal films, where quality and precision are paramount. Score slitting machines, while less prevalent, offer unique advantages in applications where controlled tearing is desired, such as in the production of perforated films.

Application Analysis

The application segment of the film slitting machine market includes packaging, automotive, electronics, textiles, and others. Packaging is the largest application segment, driven by the increasing demand for flexible and efficient packaging solutions across various industries. The rise of e-commerce and the need for protective packaging further fuel demand in this segment. Automotive applications are also significant, with slitting machines used to produce materials for interior and exterior components. The electronics industry, with its focus on miniaturization and precision, relies on advanced slitting technologies to produce components and packaging materials.

In the textiles industry, film slitting machines are used to produce materials for clothing, home furnishings, and industrial applications. The demand for high-quality finishes and precise cuts drives the adoption of advanced slitting technologies in this segment. Other applications include the production of films for medical and agricultural uses, where precision and efficiency are critical. The diverse range of applications highlights the versatility of film slitting machines and their importance in various industries.

Material Analysis

The material segment of the film slitting machine market includes plastic, paper, metal, and others. Plastic is the dominant material, driven by its versatility and widespread use in packaging applications. The demand for lightweight and durable packaging solutions fuels the adoption of plastic films, which require precise slitting processes. Paper is another significant material, particularly in applications where sustainability and recyclability are priorities. The increasing focus on eco-friendly packaging solutions drives demand for paper films and the slitting machines that produce them.

Metal films, while less common, are used in specific applications where strength and durability are required. These films are often used in the automotive and electronics industries, where precision and quality are critical. Other materials, including biodegradable and composite films, are gaining traction as manufacturers seek to meet sustainability goals. The choice of material depends on the specific application requirements, with manufacturers continuously innovating to develop machines capable of handling diverse materials and designs.

Regional Analysis

The film slitting machine market is segmented by region into Asia Pacific, North America, Latin America, Europe, and Middle East & Africa. Asia Pacific is the largest market, driven by the region's booming manufacturing sector and increasing demand for packaging solutions. The rise of e-commerce and the focus on sustainability further fuel growth in this region. North America is another significant market, with a strong emphasis on technological innovation and efficiency. The region's robust packaging industry and focus on sustainability drive demand for advanced slitting machines.

Europe, with its strong manufacturing base and emphasis on precision engineering, is a key market for film slitting machines. The region's focus on sustainability and innovation supports market growth, although regulatory challenges related to environmental concerns pose hurdles. Latin America and Middle East & Africa, while smaller markets, offer significant growth potential due to increasing industrialization and demand for packaging solutions. The diverse regional dynamics highlight the importance of understanding local market conditions and tailoring strategies to meet specific needs.

Film Slitting Machine Market Segments

The Film Slitting Machine market has been segmented on the basis of

Type

- Razor Slitting

- Shear Slitting

- Score Slitting

Application

- Packaging

- Automotive

- Electronics

- Textiles

- Others

Material

- Plastic

- Paper

- Metal

- Others

Region

- Asia Pacific

- North America

- Latin America

- Europe

- Middle East & Africa

Primary Interview Insights

What are the key drivers for the film slitting machine market?

What challenges does the film slitting machine market face?

How is the e-commerce sector impacting the film slitting machine market?

What opportunities exist in the film slitting machine market?

How are technological advancements shaping the film slitting machine market?

Latest Reports

The RFID-Enabled Shipping Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.2 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The Tracking-Enabled Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.1% during the forecast period 2025–2033.

The Warehouse-Ready Packaging market was valued at $45 billion in 2024 and is projected to reach $75 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The export packaging market was valued at $150 billion in 2024 and is projected to reach $230 billion by 2033, growing at a CAGR of 4.8% during the forecast period 2025–2033.

The pallet wrapping packaging market was valued at $8.5 billion in 2024 and is projected to reach $12.3 billion by 2033, growing at a CAGR of 4.2% during the forecast period 2025–2033.

The stretch film packaging market was valued at $12.5 billion in 2024 and is projected to reach $20.3 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The shrink film packaging market was valued at $4.5 billion in 2024 and is projected to reach $7.8 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The connected packaging market was valued at $31.2 billion in 2024 and is projected to reach $82.1 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The active packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The Intelligent Packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The IoT-Enabled Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The NFC Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The RFID Packaging market was valued at $12.5 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The sensor-enabled packaging market was valued at $18.5 billion in 2024 and is projected to reach $45.3 billion by 2033, growing at a CAGR of 10.5% during the forecast period 2025–2033.

The Temperature-Indicating Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.8 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The Time-Temperature Indicator (TTI) Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Anti-Microbial Packaging market was valued at $10.5 billion in 2024 and is projected to reach $18.7 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The Oxygen Scavenger Packaging market was valued at $1.8 billion in 2024 and is projected to reach $3.2 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The moisture absorber packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Ethylene Absorber Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Spoilage Indicator Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Tamper-Aware Smart Packaging market was valued at $2.5 billion in 2024 and is projected to reach $6.8 billion by 2033, growing at a CAGR of 11.5% during the forecast period 2025–2033.

The connected beverage packaging market was valued at $1.2 billion in 2024 and is projected to reach $3.5 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The QR-Code Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The AR-Enabled Packaging market was valued at $2.5 billion in 2024 and is projected to reach $12.8 billion by 2033, growing at a CAGR of 20.1% during the forecast period 2025–2033.

The RFID-Enabled Shipping Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.2 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The Tracking-Enabled Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.1% during the forecast period 2025–2033.

The Warehouse-Ready Packaging market was valued at $45 billion in 2024 and is projected to reach $75 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The export packaging market was valued at $150 billion in 2024 and is projected to reach $230 billion by 2033, growing at a CAGR of 4.8% during the forecast period 2025–2033.

The pallet wrapping packaging market was valued at $8.5 billion in 2024 and is projected to reach $12.3 billion by 2033, growing at a CAGR of 4.2% during the forecast period 2025–2033.

The stretch film packaging market was valued at $12.5 billion in 2024 and is projected to reach $20.3 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The shrink film packaging market was valued at $4.5 billion in 2024 and is projected to reach $7.8 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The connected packaging market was valued at $31.2 billion in 2024 and is projected to reach $82.1 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The active packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The Intelligent Packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The IoT-Enabled Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The NFC Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The RFID Packaging market was valued at $12.5 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The sensor-enabled packaging market was valued at $18.5 billion in 2024 and is projected to reach $45.3 billion by 2033, growing at a CAGR of 10.5% during the forecast period 2025–2033.

The Temperature-Indicating Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.8 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The Time-Temperature Indicator (TTI) Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Anti-Microbial Packaging market was valued at $10.5 billion in 2024 and is projected to reach $18.7 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The Oxygen Scavenger Packaging market was valued at $1.8 billion in 2024 and is projected to reach $3.2 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The moisture absorber packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Ethylene Absorber Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Spoilage Indicator Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Tamper-Aware Smart Packaging market was valued at $2.5 billion in 2024 and is projected to reach $6.8 billion by 2033, growing at a CAGR of 11.5% during the forecast period 2025–2033.

The connected beverage packaging market was valued at $1.2 billion in 2024 and is projected to reach $3.5 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The QR-Code Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The AR-Enabled Packaging market was valued at $2.5 billion in 2024 and is projected to reach $12.8 billion by 2033, growing at a CAGR of 20.1% during the forecast period 2025–2033.